For years now, a diverse range of beverage products containing alcohol has fuelled continuous growth in the segment. Ready-to-drink (RTD) products include beer and cider, as well as other beverages containing alcohol mixed with sodas, fruit juices or other non-alcoholic drinks.

The Distell Group, one of Africa’s leading producers of spirits, premium wines, ciders and other RTDs, decided to convert its plant from a batch process to an in-line process that is controlled by measurement of the concentration in degrees Brix.

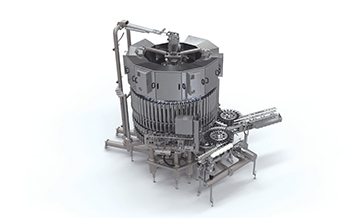

Centec GmbH, a supplier of fully automatic, skid-mounted process equipment and high precision measurement, was contracted to deliver the following equipment as part of the Distell Springs project:

- 150 hectolitres/hour column water de-aeration unit with UV disinfection and storage tank;

- 400 hectolitres/hour mixing unit for fruit juice;

- 400 hectolitres/hour aeration unit for fruit juice;

- 430 hectolitres/hour mixing system incorporating up to 13 different liquid product streams.

De-aeration unit

To produce high-quality beverages with long shelf life, the oxygen content of the water must be reduced to a very low concentration. Centec incorporated oxygen sensors in the processing equipment that can detect concentrations from 1 ppb (parts per billion) to 2 ppm (parts per million) with an accuracy of ± 1 ppb.

Alcohol can be measured over a range of 0-100% by volume with an accuracy of ± 0.02%. The sensor for determining °Brix has a measuring range of 0-80 °Brix with an accuracy of ± 0.02 °Brix.

The water de-aeration process takes place at ambient temperatures. To begin, the water is distributed throughout the upper portion of the column. The column contains densely packed, thin stainless steel sheets arranged in such a pattern that the water is forced to take many routes as it flows downwards through the column.

This maximises the surface area for gas transfer and the contact time between the water and the stripping gas (CO2). The stripping gas is fed into the base of the column and rises upwards through the column, counter current to the flow of the water.

The significant difference in partial pressure drives the oxygen from the water and into the gas phase. At the top of the column, the oxygen removed from the water exits the system in the gaseous state along with the residual stripping gas.

The water reaching the base of the column has an oxygen content of less than 30 ppb. From there, it passes through a UV system for disinfection and flows to a 350 hl storage tank.

The entire production facility is supplied with de-aerated water from this storage tank. The water is transported under a pressure of three bars to various extraction points throughout the facility.

Detecting oxygen

The oxygen concentration in the de-gassed water is constantly monitored using

Oxytrans, an optical oxygen sensor that can detect and measure concentrations of oxygen in water between 1 ppb and 2 ppm with an accuracy of ± 1 ppb.

The optical technology is based on the energy released through a phase change, which is re-distributed through molecular interaction without radiation. A small glass component with a thin layer of indicator molecules, an “optical window” of sorts, is installed in the measuring head of the device.

The indicator molecules are exposed to a blue-green light source which is generated by an LED in the sensor. The molecules absorb the incident light. The resultant excitation elevates the molecules to a higher energy state.

After a defined time has elapsed, the molecules revert to their ground state, causing the emission of red light that is then detected by the sensor.

If O2 molecules are present, the energy from the excited indicator molecules is transferred to the oxygen. The detection signal from the sensor weakens as the concentration of O2 molecules increases in the product.

Other gases do not absorb this energy, and therefore, they do not affect the measurement results.

Mixing juice

Each recipe is based on a specific ratio of various ingredients. If a specific recipe is selected while the system is in operation, the entire mixing procedure is carried out automatically.

Coriolis mass flow meters are employed for high precision process control. Flow meters, which operate based on the Coriolis principle, contain measuring tubes that vibrate when acted upon by a force.

When a medium flows through a vibrating tube, Coriolis forces are generated that bend the tube. Sensors detect the change in the vibrational frequency of the tube.

The phase shift of the sensor signals is directly proportional to the mass flow. The density of the medium can be determined using the vibrational frequency of the measuring tubes.

Mass flow meters can also measure the temperature of the medium. A microprocessor converts the digital signals to document the mass flow, density and temperature of a medium.

After a recipe is selected, the flow of input streams is accurately controlled at all times, while automatically compensating for any effects due to any differences in temperature which may occur.

To avoid dead spaces, the processing system is equipped with mix-proof double-seated valve technology.

3-stream systems

A Combitec in-line sensor is employed to ensure that the final product always contains the exact sucrose content specified for fermentation. The sensor is perfectly suited for three-stream systems and is capable of determining density, concentration and the speed of sound simultaneously.

The density measurement is based on the oscillating U-tube principle. To measure the sound velocity, a sonic pulse is generated by an ultrasonic transmitter and detected by an ultrasonic receiver.

The relationship between concentration and density or speed of sound is a property specific to each fluid and can be described by a mathematical polynomial.

In an aqueous solution, sucrose splits into glucose and fructose. This reversible process is known as “hydrolysis”. With the Combitec device, it is possible to measure the individual components and to determine the sucrose content with an accuracy of ± 0.02 °Brix. After mixing, the product is pasteurised and then aerated.

Fruit juice is aerated to increase the activity of the yeast and start the fermentation process. The unit is equipped with a specially dimensioned Vortex-Venturi injector to aerate the product.

A very large number of tiny oxygen bubbles are injected directly into the product stream with this unit. The oxygen dissolves completely in the medium due to high pressure and turbulent flow conditions.

A control valve is installed at the end of the segment where the oxygen goes into the solution. This valve maintains a constant pressure within the system, above the saturation pressure.

To precisely control the target flow of both fruit juice and oxygen, the air runs through a Coriolis mass flow meter with an accuracy of ± 0.5 % v.M., while the fruit juice flows through a magnetic-inductive flow meter which has an accuracy of ± 0.2 v.M.

The aerated juice destined for cider production has an oxygen content of 20 mg/litre. The juice passes through the yeast dosing station on its way to the fermentation tanks.

Mixing streams

In the first phase of the project, a system was designed and constructed to enable a fermented product to be mixed with up to eight different streams of liquid ingredients.

Today, after undergoing expansion, this system is now capable of mixing a total of 13 different streams with a fermented product.

The individual streams feeding into the system are equipped with Coriolis mass flow meters, which are accurate to ±0.1% by v.M. For every recipe formulation, the proportions are specified for each stream, allowing the target ratios to be reliably achieved with automatic compensation for any fluctuations in temperature.

Here, mix-proof, double-seated valve technology is utilised as well.

The concentration of alcohol and °Brix are measured in the finished products using an in-line Combitec sensor integrated into the mixing system. Centec’s own measuring device is used for process control.

Measurements of the finished products are accurate to ±0.025% by volume for alcohol and to ±0.03 °Brix.

All systems can be cleaned using common industrial protocol and are equipped with a Siemens Simatic S7 controller. A virtual private network router allows remote access to the system via the internet at any time.

– Centec GmbH is based in Frankfurt-Maintal (Germany) with subsidiaries on all continents and a network of qualified sales and service partners. The 40-year-old company specialises in automation and assembly, switch cabinet construction and tank manufacturing, with exports to all parts of the world.