The juice, nectar and still drinks (JNSD) portion of the beverage industry is stable and conservative in many ways, with industrial practices built up over decades to ensure product safety and efficient production processes. So it isn’t often that something new comes along to shake things up.

As so much of JNSD builds upon the quality of water blended in these beverages, scientists at Tetra Pak examined and explored how they could re-configure the processing of ingredients while maintaining product safety and shelf life – and achieve much lower processing costs as a result.

They did this by combining existing technologies – filtration and UV treatment – which can be used to purify water before it is blended with the other beverage ingredients. Their experimentation and innovative equipment and processing parameters yielded extremely satisfying results.

While maintaining product safety and quality, this new JNSD line solution can greatly cut down energy-consuming heat treatments – reducing overall energy costs by about 67%. It also reduces water used in cleaning in place (CIP) and sterilisation in place (SIP) by about 50%.

Natural acidity

The engineering concepts the scientists tested and verified are relatively straightforward. JNSD beverages, including teas, have a pH level <4.2. In other words, beverages that tend to be on the acidic end of the scale.

This is because the natural acidity of fruit counteracts some of the common micro-organisms that lead to food spoilage.

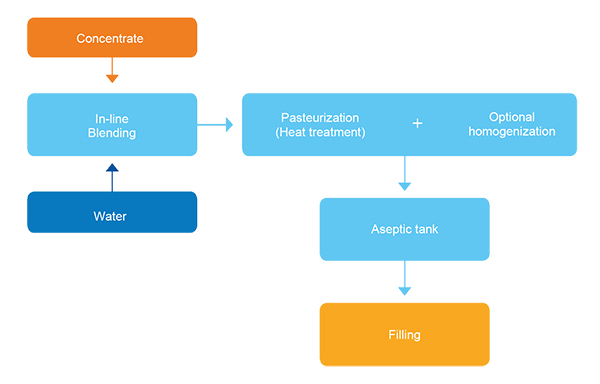

In JNSD solutions commonly used today, all ingredients are blended with water to give the final beverage, before going to the pasteuriser for heat treatment, in order to deactivate harmful micro-organisms. This can be done with either in-line blending or batch blending.

Basic steps in the process.

The problem with this general approach is that pasteurisation requires a great deal of energy to treat the entire beverage volume. This is true even with modern pasteurisers which, by using regenerative heat, are very efficient at heating and cooling.

Moreover, when the system volume is large – 2,000 litres, for example – it means each product change creates a large product loss. In addition, CIP and other cleaning steps may require several system volumes to fully execute, which by themselves require additional water, energy and other resources.

Clearly, this is a process that could benefit from re-analysis. If Tetra Pak wanted to transform a JNSD line to make it more energy-efficient and save operating costs, what would it look like?

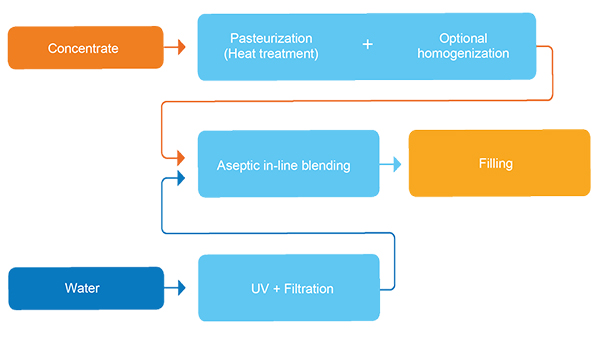

Low-energy JNSD line.

New approach

One approach that has already been tried and commercialised is to add water in the form of steam to the concentrate, followed by dilution with cold water. Other innovative approaches in the industry have focused on achieving required quality levels, but not necessarily saving energy costs.

Tetra Pak scientists decided to take a new approach. They re-imagined the JNSD line by splitting the process into two separate streams and treating these two streams differently before blending: concentrate and water.

Traditionally, the full volume (concentrate and water) is pasteurised and the most energy-intensive process step is heat treatment. In the new line concept, the scientists pasteurised the smallest possible volume of product, in this case the concentrate.

The rest, which is water, is treated separately using more cost-effective aseptic technologies such as filtration, UV light, or a combination of both. Furthermore, there may be different target organisms when considering UV, filtration, or heat treatment.

A solution using only UV would result in unacceptably high energy consumption as a very high UV dose would be needed to treat the high resistance of potential spoilage organisms.

The optimal solution is thus to combine two methods: using a filter to ensure the reduction of spoilage organisms and UV to ensure the required reduction of pathogens.

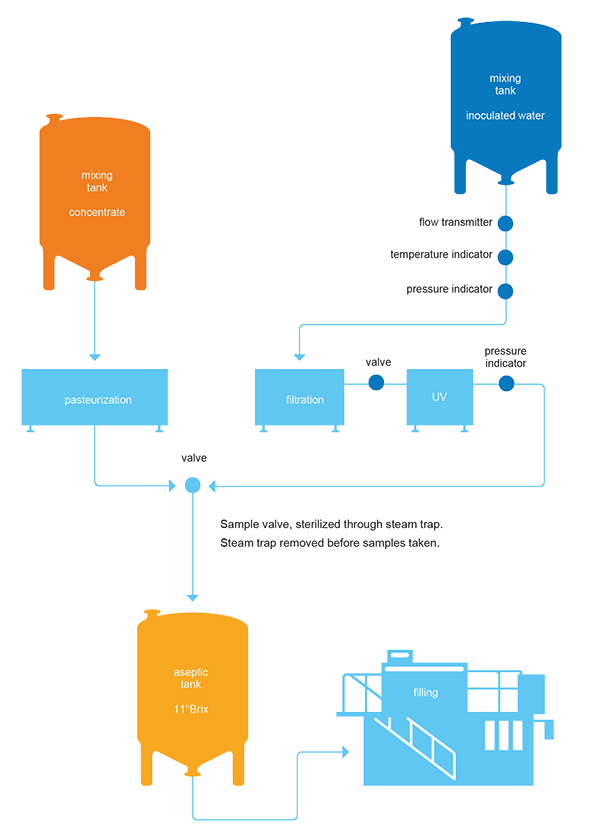

To verify that the combination of UV treatment and filtration of the water gives the required logarithmic reductions of the target organisms, the scientists built a pilot test facility that combined a tank for juice concentrate, heat exchanger for pasteurisation of juice concentrate, tank for water inoculated with target organisms, UV equipment, filter house, aseptic sample valve for the water, aseptic tank and filling machine.

They calculated the operational cost for UV and filter solution, focusing mainly on energy consumption, CIP costs and water consumption. The scientists also evaluated the capital (investment) costs of buying and installing the new equipment.

Tetra Pak’s pilot plant.

Operating costsThe estimated operating cost for the current solution is €138,000 per year. With the new low-energy solution the operating cost for treatment of the water with filtration and UV is estimated at €12,000 per year, and the heat treatment of the concentrate at €34,000 per year, totalling an operating cost of €46,000 per year.

This represents a saving of €92,000 per year, or 67%, compared to the current solution. The water consumption is estimated to decrease by 50% from 96,000 litres per week to 48,000 litres per week when implementing the low-energy solution, thus surpassing the target for decreased water consumption.

The customer investment costs for the current and the low-energy solutions are based on a system capacity of 32 cubic metres per hour. The choice of UV equipment and effective UV dose was arrived at by extensive experimentation, based on a UV transmission of 90% in the water.

Given the final choice of UV equipment, the additional investment cost to the customer was only 5% more than the current solution. This additional cost is paid back well before the returns-on-investment target of a maximum of 6 months.

Combining filters and UV treatment with the correct specifications, Tetra Pak scientists and engineers constructed a pilot line to validate this low-energy treatment concept, and ran operational tests involving nearly 8,000 juice packages. The findings were highly successful.

Tetra Pak is now actively seeking beverage producers who would like to test its low-energy JNSD line concept in their plants, with their beverage formulations. Tetra Pak also has pilot plants where trials are conducted for customers on-site with the support of its expertise. For further information, write to maria.norlin@tetrapak.com.