Three Japanese breweries use it for CO2 and O2 removal, to prevent pipe corrosion

In the food and beverage industry, there is a growing awareness of environmental considerations wherever chemicals are used. In response, companies are trending towards alternative systems that operate with less chemical usage.

Kirin beer has been successfully using 3M Liqui-Cel membrane contactors for CO2 and O2 removal in their Okayama, Hokuriku and Kobe facilities in Japan. The contactors successfully prevent corrosion of pipes that feed the boiler without using high volumes of neutralizing amine chemicals that negatively impact the environment.

CO2 is formed when water containing dissolved salts, such as sodium bicarbonate, is heated in a boiler. This process is illustrated in the diagram below. The CO2 dissolves into condensed water in the pipes; this creates an acidic environment that will attack the inner surface of the pipe. O2 is another known corrosive element in water used to feed the boilers.

Kurita Water Industries Ltd. incorporates Liqui-Cel membrane contactors in their Oxyace System, which they installed to remove the CO2 and O2 in front of the boiler at Kirin Beer to prevent pipe corrosion.

Removal method

In order to prevent the formation of CO2 in the steam, sulfuric acid can be added to the feed water. The sulfuric acid reacts with the sodium bicarbonate and forms sodium sulfate, carbon dioxide and water. This is illustrated in the chemical equation 2NaHCO? +H?SO? >Na?SO? +2H2O +2CO?.

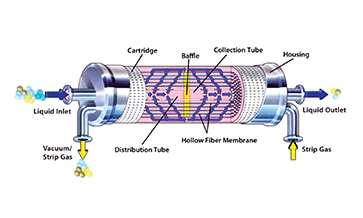

Membrane contactors are unique devices that are designed to remove dissolved gasses from water. In this system, they remove dissolved CO2 and oxygen that are present in the water.

The Oxyace system includes a softener, filtration, pH control (M-Alkali control), 3M Liqui-Cel membrane contactors and a vacuum pump. With system automation and a feedback signal, the soft water is controlled to a pH of 5.0 with sulfuric acid. Caustic soda is added daily to inhibit bacteria growth. Very minimal chemical usage is required to control the pH.

To date there are 14 Oxyace systems operating in Japan. All these systems utilise Liqui-Cel membrane contactors for degassing. For additional information, contact your 3M representative or visit 3M.com/Liqui-Cel.