Most whisky traditions are costly, some are priceless! So says technology provider Siemens. The company recently partnered with Johhnie Walker owner Diageo to come up with a digitised whisky cask-filling system that could save millions of pounds in wastage.

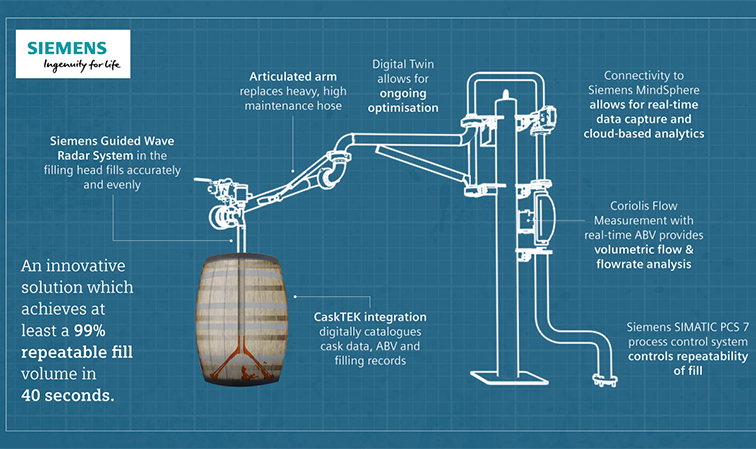

The project’s partners include the Glasgow-based University of Strathclyde’s Advanced Forming Research Centre (AFRC) and electrical expert Kigtek. Together they have invented an innovative whisky cask-filling test rig that will include a “digital twin” that replicates the physical process in a virtual environment.

The Scotch whisky industry is worth £5.5 billion (US$ 6.9 billion) annually to the UK economy. Cask production accounts for up to 20% of the overall cost of whisky making. Diageo, the world’s biggest Scotch whisky distiller, holds more than 11 million casks in maturation at any time.

The variability in size and volume of traditional wooden casks, combined with traditional filling methods, has meant that unbelievably most casks still aren’t filled consistently or are overfilled. This issue is costing whisky distilleries precious productivity each year.

Other benefits

As traditional Scotch whisky casks are made from oak, the discrepancy in the volume that each can hold makes the project “particularly challenging”, the AFRC said. The new system enables a “high degree of repeatability”, as well as improvements to health and safety, and reduces waste.

The innovation tackles the problem of inconsistent cask-filling levels resulting from overspill, under-fill and foaming. It allows Diageo to account for every drop that goes into each cask, achieving more than 99% fill consistently on a 200-litre cask – in less than 60 seconds!

Danny McMahon, digital manufacturing team lead at the AFRC, said: “The digital twin system achieved as the output of this project will allow Scotland’s whisky industry to truly embrace ‘Industry 4.0’ using data to digitise a traditional process.”

The collaboration with Siemens’ instrumentation know-how, Kigtek’s process and control understanding, and Diageo’s industry knowledge, will allow distillers to save “significant” capital expenditure from logistics and warehouse space for additional casks.